What is it

An arc flash incident may occur as a result of a short circuit or fault where the electric current moves away from its normal path and instead conducts through the air. An arc flash can occur as a result of reduced integrity of insulated areas, corrosion of equipment, accidental touching, condensation, accumulation of dust and faulty installation.

An arc flash incident may occur as a result of a short circuit or fault where the electric current moves away from its normal path and instead conducts through the air. An arc flash can occur as a result of reduced integrity of insulated areas, corrosion of equipment, accidental touching, condensation, accumulation of dust and faulty installation.

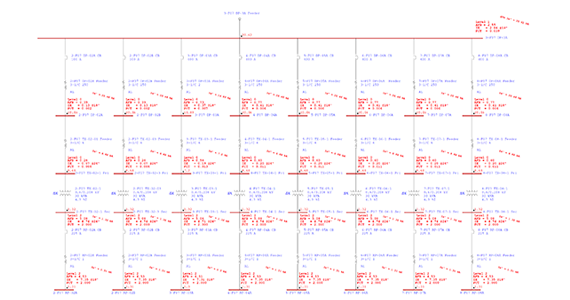

Exactly which one of these causes is affecting a particular electric system can be determined by the completion of an Arc Flash Study. The study will collect data regarding the power distribution system, including the details of the components in the system, their arrangements, dimensions of all cables and protective device settings.

Why is it needed

An arc flash is a very dangerous event that can cause serious damage to equipment, and life-threatening injuries to workers. The large amount of energy expelled during an arc flash produces very high temperatures. These temperatures can ignite combustible materials in close proximity, liquefy metals in the system leading to explosive pressure changes capable of turning loose objects into projectiles. These pressure waves are also associated with sound blasts that can permanently damage the hearing of nearby workers.

How can we help

Engineers use results of short-circuit study and protection co-ordination study to perform arc-flash hazard analysis. Based on the arc-flash hazard analysis our team will:

- Quantify the potential for arc hazards at specific locations

- Provide methods to mitigate or minimize the hazards to electrical workers

- Warning labels will be assigned to each piece of equipment based on its potential to cause damage.

- Protection boundaries will be assigned past which Personal Protective Equipment must be worn.

Information can be used as a basis to

- Develop strategies to minimize injuries

- Specify rating and type of personnel protective equipment (PPE)